Hello again!

So I am back again to provide a clearer view of GAIN, the programs this organisation has been running over the years and just how my project fits in to what they have been doing;

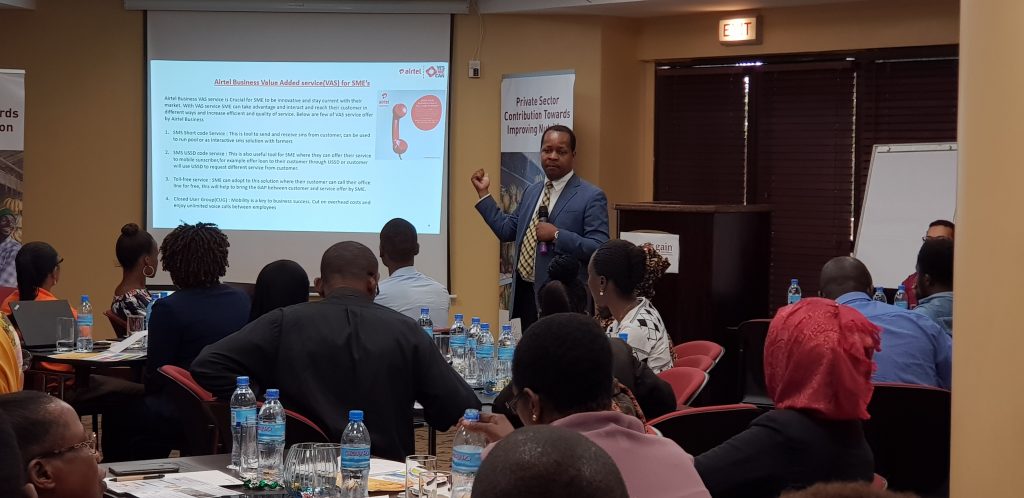

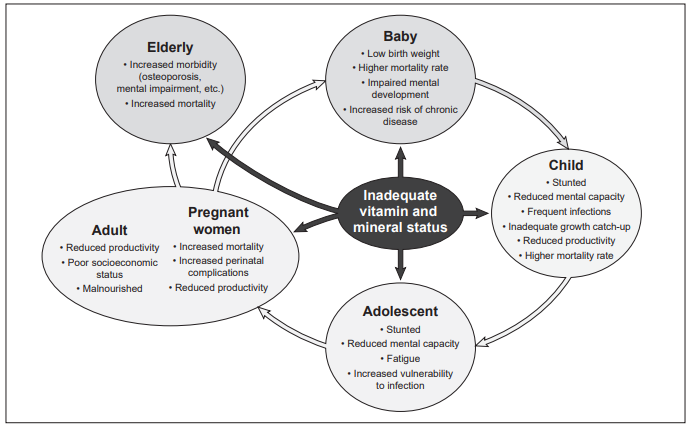

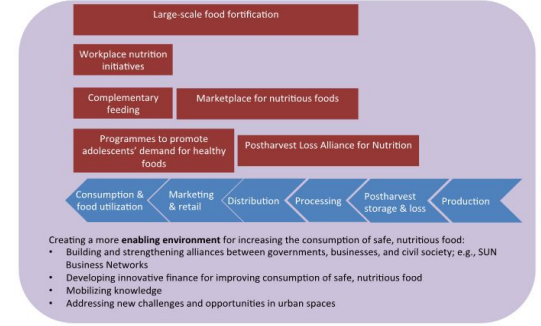

In the year 2002, Global alliance for Improved Nutrition (GAIN) was officially established with a goal of working together with public and private sectors to end malnutrition (Moench-Pfanner and Van Ameringen, 2012) . GAIN has adhered to this commitment by striving to making healthier food choices more affordable, more available and more desirable. In these efforts GAIN, has leveraged to improve nutrition outcomes by enhancing the consumption of nutritious and safe food, especially to the vulnerable, in recognition that the food system can only be fixed by a collective global effort. Their work has been organized into different following programme areas, operating in an interlinked way along the food value chain, concurrently cooperating with various partnerships and alliances as described in fig 1.

To enhance nutrition outcomes by improving the consumption of nutritious and safe food for all people, especially the most vulnerable. – GAIN’s Vision and Purpose

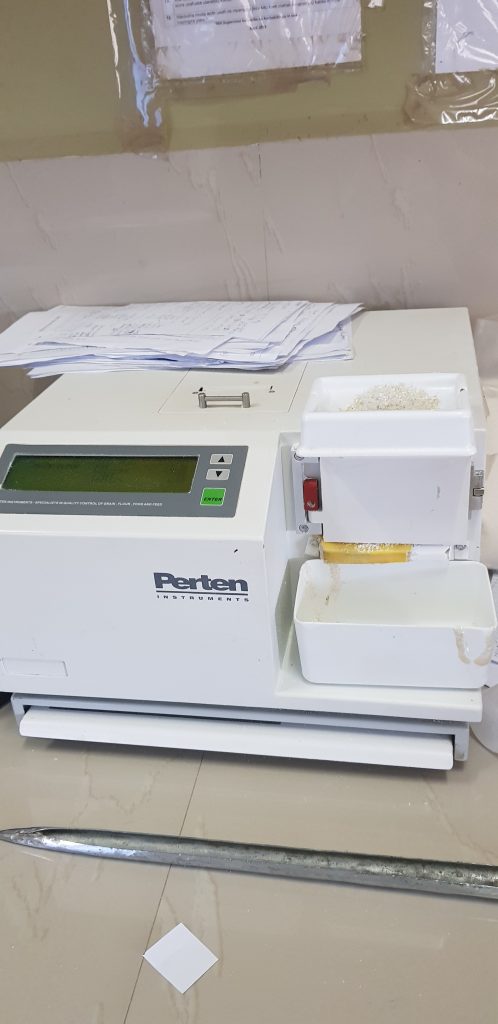

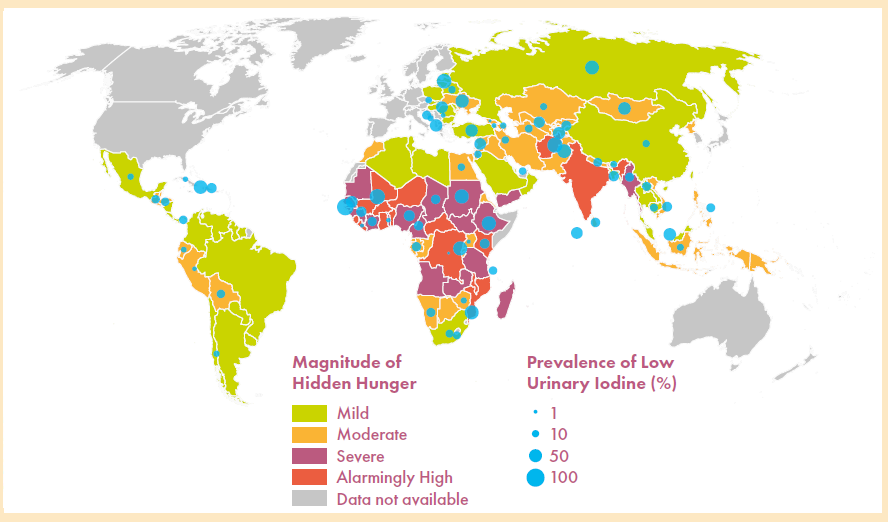

One of GAIN’s major programs has been that of large-scale fortification of food, whereby the program was initially launched in 2003 (Guinot et al., 2012). Within less than a decade these operations have been upscaled to reach more than 610 million people with nutritionally enhanced food (Moench-Pfanner and Van Ameringen, 2012) as described in figure 2.

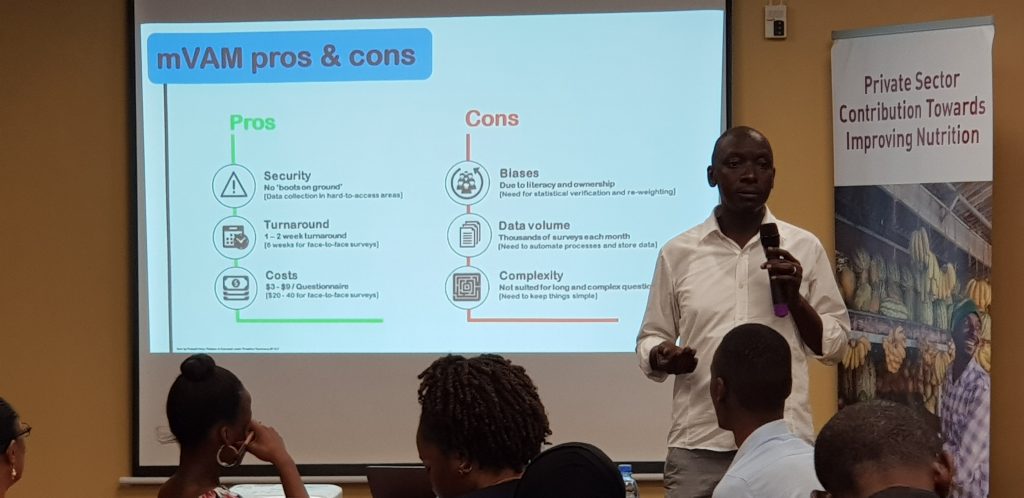

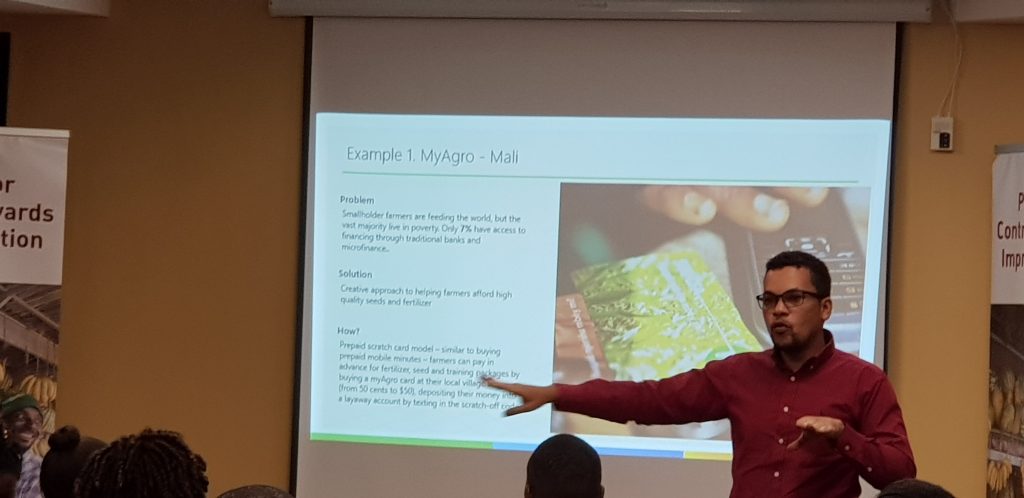

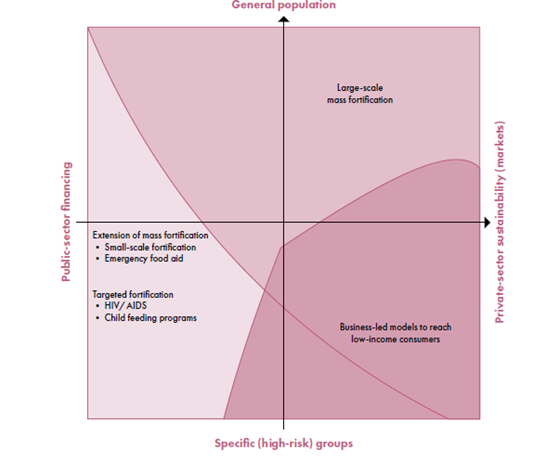

GAIN’s strategy towards large-scale food fortification, which has developed extensively (through the years due to initial challenges) , involves development of complementary approaches for the delivery of fortification recognizing the limitations of large-scale fortification to reach the entire population in some countries . The framework below, developed by GAIN, displays how various program delivery approaches can complement one another and reach different groups of the population. The objective of the layered approach includes; firstly, to attain a wide coverage of the total population as possible; and secondly to make certain that targeted nutrition interventions meet the needs of specific high-burdened segments of the population (Moench-Pfanner and Van Ameringen, 2012).

However, while, its globally significant to ensure that food is nutritious and secure, it is also essential that such efforts do not antagonize various endeavors already present in dealing with climate change or do not contribute to worsened impacts on the environment. Thus, it is important to be able to categorize and understand the relevance that approaches such as food fortification have in relation to adapting to the Earths changing climate (Adaptation) and reducing Greenhouse gas emissions (GHG) (Mitigation) (Harvey et al., 2014)

How does my project fit in?

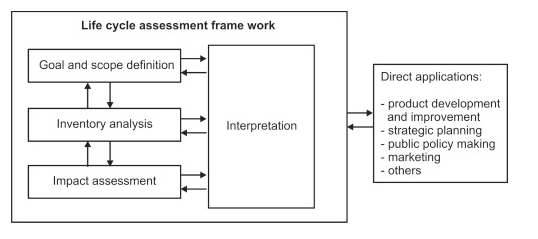

My project aims to support GAIN’s work by specifically focusing on large-scale food fortification seeking to understand where it stands in terms of its impact to the environment . The research goal, in pursuit of ensuring a continued delivery of quality nutritional outcomes, aims to map out major hotspots within fortification value chains of wheat and maize, that impact the climate by assessing their associated carbon equivalents.

The objective of this analysis simply seeks to;

To provide a comprehensive review of the resource footprint of food fortification value chains of wheat and maize and attempt to review its impact pathway.

To analyse the supply chain sustainability of constituents necessary for food fortification delivery in East Africa, identifying the lowest -resource footprint options

To categorize how large-scale food fortification can directly and indirectly contribute to adaptation of climate change in East Africa.

In my next post, I will discuss on research findings, interpretations, research challenges and possible areas for future research.

Cheers!