As I mentioned, in my last post, my visit to Arusha was mainly aimed at visiting large-scale industrial sites for the specific food vehicles I am looking at. I thus, visited Kijenge Animal Products (Ltd) , specifically looking at their Ken-milling industry (as the site also comprises of a feed-mill and coal industry). Additionally, I visited Jimbo industry which processes wheat.

I never really imagined that so many processes and machinery are involved in maize and wheat flour production, however is was a great learning experience.

The industry staff where cooperative and ran me through the whole procedure involved from receiving raw kernels, cleaning, milling and packaging products. They where also willing to share records of production describing volumes received, cleaned, screened, co-products produced and final product quantities. These records also indicate the various electricity and fuel quantities needed for production. Below, I share briefly the steps involved in production of fortified maize flour (as wheat flour production is quite similar) and the lessons learnt:

Step 1 of processing: Receiving

Maize is received from different areas in Tanzania including Kiketo, Singida, Arusha, Tunuduma and Babati . The Kenmill industry receives an estimate of 60 tonnes per day. The off loading work is performed manually, and an elevator is used to arrange maize packages in store areas.

An procedure is performed to assure the quality of the maize acquired. Random samples are taken from different maize bags and tested. Poor quality maize eg, maize infected my alfatoxins that is not fit for human consumption is rejected. This rejected wheat is often taken to the Kap-feeds and utilized as food for animals eg. chicken. If the quality is too poor it is thrown away- landfill.

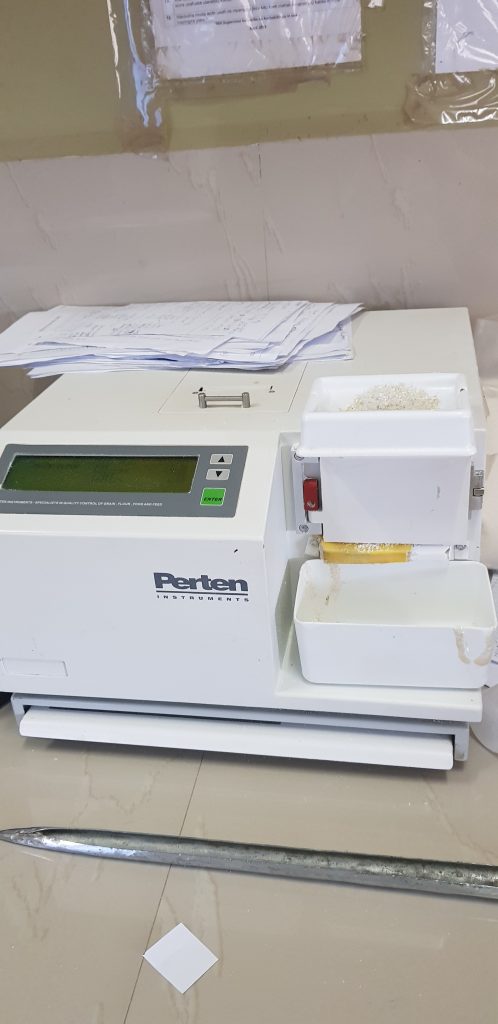

This is a grinder machine used to grind maize into small sample particle to be analysed

Lab sifter used to analyse various small particles. Particles are sifted to differ according to the standards required eg, larger particles

There are quality control analysis forms that keep records of results of samples tested. Features analysed according to standard parameters within maize kernels include: foreign matters, infestation, sprouted maize kernels, moldy grain, heat and insect damaged kernels, immature, musty odored and kernels that are contaminated. The moisture content is also measured.

Step 2: Cleaning

This stage involves removal of unwanted objects so as the maize kernels will be clean for processing. The process takes away chaffs, stones, metals, sticks, dust etc. All foreign material and all that is not maize kernels from the to-be milled grain that lowers the quality of the product such as husk, straw, sand, and everything too big or too small and lighter than a maize.

At each stage, a scale measures the volume quantities of maize that progresses through to next stages and volumes of waste released.

Step 3: Conditioning

Conditioning refers to the addition of moisture (water) to the maize to allow the bran to be peeled off in flakes before milling with plate or roller mills. This allows easier separation in a sifter and, most importantly to add mass to the meal.

Step 3: Milling

Maize that is hammer milled would generally represent an undefined class, probably closest associated with special sifted maize meal and represents the lowest cost option and more appropriate for many rural applications. This form of maize is known as bran. Bran produced is collected by a bran-collector.

The roller-mill machine grinds maize, Maize that is grinned is passed through a sifter that separates the particles accordingly. Maize is milled concurrent to different grading depending on its utilization. Particle sizes may differ say for flour to be used for breweries or normal flour used for consumption.

Step 4: Fortification process

Fortification occurs as one of the final procedures to milled flour. The milled flour is passed through conveyors towards a machine that adds specific amounts of premix mixtures (fortificant combinations) to the flour. The amounts of these micro-nutrients added are minimum whereby 0.5 kg of premix is added to 1 tonne of maize flour according to East African Standards, 2012. East Africa standard fortification mix comprises of Vitamin A, Vitamin B1, Vitamin B2, Niacin, Vitamin B6, Folate, Vitamin B12, Iron and Zinc. Tanzania however, fortifies it flour with all micro-nutrients mentioned except Vitamin A.

Step 5: Packaging

There is small packaging ( 1- 10 kg) and large packaging (25-50 kg). These are than stored in wait for there distribution to various areas.

Products on transit..

The process above utilizes electricity. The amount of production varies between seasons depending on the availability of maize according to the production manager. The industry is able to process 75 tonnes in 24 hours.

Additionally, there is a quality assurance check from each stage of production to ensure the flour produced meets the standards for consumption. Thus samples are taken at each stage and measured concurrent to the grading required.

In the coming posts, I am going to clearly outline what my project seeks to assess and the relevance of visiting these large-scale fortification industrial sites and also how this fits in with GAIN’s objectives for the future.

That will be all for today…

Cheers!