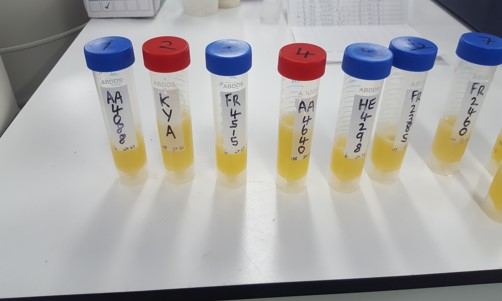

All samples go through quality control before been processed. A 20 µl drop of semen is placed on a microscope slide and covered with a coverslip and observed under 40x objective lense to asses the total motility (%) and progressive motility (1-5 scale) of the sample. If samples achieve a score over 70% for total motility and 3 for progressive motility they can go through production. The raw semen is diluted in Isoton and the concentration of each sample is determined using a Beckman Coulter count and size analyser. Straws require a certain concentration of sperm in each sample, 20 x 106 sperm/ml for beef and 15 x 106 sperm/ml for dairy bulls.

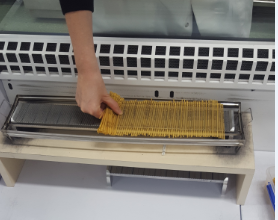

Each tube is weighed in order to determine the ejaculate volume. Each sample is then diluted in a media containing egg yolk, purified water and BullXcell (contains antibiotic properties) into a duran. The filling machines are then prepared and the straws are filled with diluted semen. The straws are then frozen in liquid nitrogen vapour and the freeze curve drops to -130⁰C over a seven minute cycle. Post freeze the straws are stored in tanks filled with liquid nitrogen until the following day where they will undergo another quality control assessment and a stress test. Once again viability and motility are scored. Semen that has a viability of 50% and a motility of 3 is kept. Bulls that pass these checks are then kept in quarantine for up to 30 days before been used in the field, regulations in place by the Department of Agriculture