The Platform for Accelerating Circular Economy (PACE) launched the Circular Economy action agenda on the 4th of February 2021. I am thrilled to have attended the virtual conference and excited with the plans that the governments, civil society, and business leaders shared on operationalizing the action agenda. The agenda focuses on 5 dynamic sectors which include food, plastics, textiles, electronics, and capital equipment

The world economy has gone through huge transitions, and now is the time to shift towards a circular economy as it presents a strong pillar against climate change. Moreover, devoting resources to a circular economy is crucial for the realization of the agenda 2030, the Paris agreement, the 2050 net-zero commitments, and building sustainable economic recovery post the covid-19 pandemic. Furthermore, the action agenda on capital equipment points out that changing the way capital equipment is made and used could contribute to reducing global greenhouse gas emissions by 45%. Consequently, the report shows that the circular economic model presents a US$4.5 trillion economic gain while reducing the use of raw materials during the manufacture of capital equipment, which is currently at 7.2 billion tons of raw materials per annum.

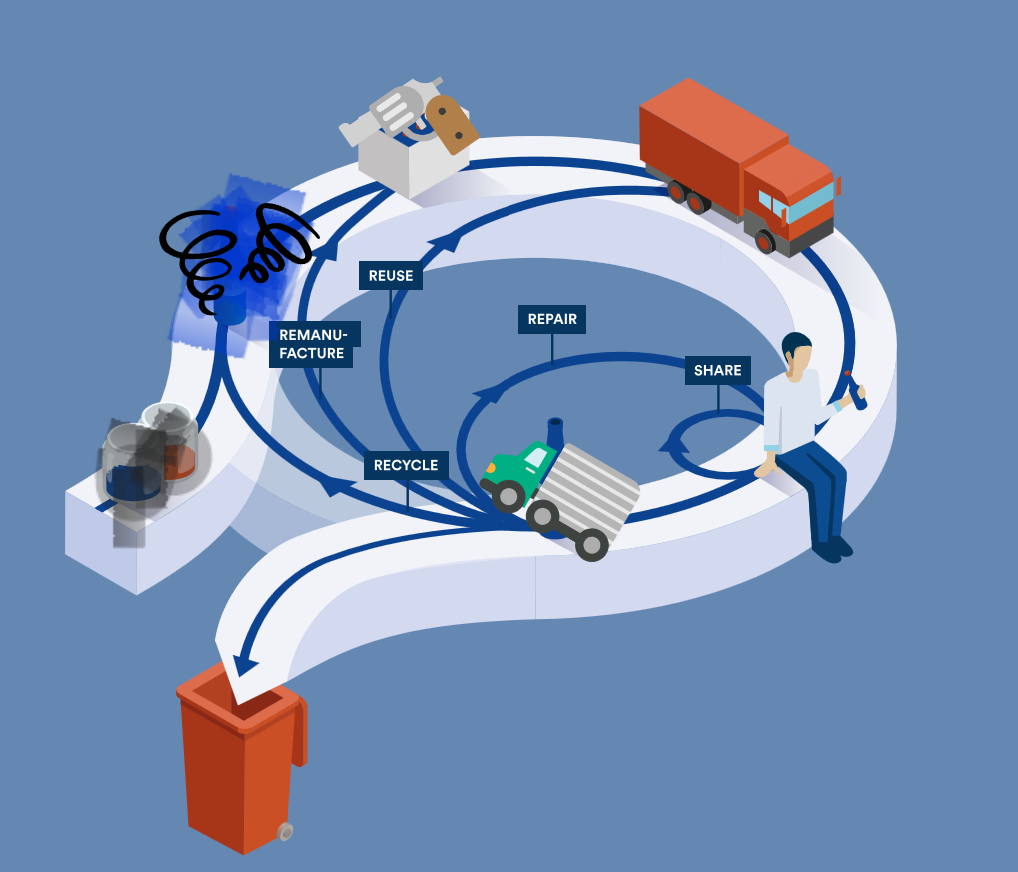

The impacts of the covid-19 pandemic on the world economies have shown the vulnerability of the linear economic model to any disturbance in the flow of resources, with agriculture being one of the most affected sectors. Therefore, the application of the circular economy in the agriculture capital equipment sub-sector could have enormous gains. Firstly, circularity in the agri-machinery industry would mean the promotion of the use of renewable energy and reusable pieces of equipment. Secondly, shared ownership or use of equipment such as tractors, combine harvesters, drones, irrigation facilities, and trucks at the cooperative or community level would be essential in attaining circularity. The application of concepts such as “machine sharing platforms” which borrows the concept of uber on agri-capital equipment could be vital in ensuring service availability and reducing pressure on raw materials used in the manufacture of huge quantity of equipment, which sometimes lay idle in warehouses, shops or is underutilized by sole owners. Thirdly, accelerating the circular agenda would require that durability of agri-capital equipment is further improved. Fourthly, putting into place efficient frameworks that strengthen the reverse logistics to enable customers to return equipment or components of equipment to the manufacture at the end of use is important if circularity is to be achieved. Additionally, ensuring an enabling policy environment that fosters reverse logistics and promotes transparency would be cardinal. Fifthly and lastly, improving the reusability of parts or components of agriculture capital equipment would be essential in reducing the waste and carbon footprint of the capital equipment industry.

Transforming the key driver of the global economy through circularity is a necessity and now is the time to act. Consequently, leveraging the agro-capital equipment circular agenda would be key in building sustainable and resilient markets, foster linkages between manufacturers and customers, and improve the working and living conditions of people. Conclusively, working towards a circular economy of capital equipment plays a critical role in preventing waste and pollution, minimizing environmental impacts, and tackling capital raw resource overconsumption, thereby leading to more resilient and sustainable economic development.