Mycelium, a promising future

Population growth, ethical concerns, and planetary and public welfare are the key intertwined issues when addressing food, and in particular meat and dairy production. The EAT Lancet Food in the Anthropocene article brought to the fore a possible framework for future food systems and ideal diet and highlights how food systems must transform to facilitate growing population while remaining within planetary boundaries (Willett et al., 2019). Avoiding meat and dairy products is considered one of the most effective means of reducing environmental impact on the planet. Farmland use could be reduced by more than 75% by eliminating meat and dairy and while meat and dairy provide 18% of calories and 37 % protein it uses 83% of farmlands and produces 60% of agricultural greenhouse gas emissions (Poore and Nemecek, 2018). This evidence also shows considerable variation between production methods. Livestock reared on deforested land can cause up to 12 times more greenhouse gasses and use 50 times more land. The increase in demand for healthy options and concern about rise in meat prices and the environmental impact of meat have spurred interest in the development of analogue meat products.

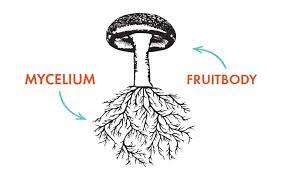

Mycelium is the vegetative part of a fungus and consists of hyphae, a mass of thread like filaments.. By naturally fermenting mycelium and using the mycelium network as a scaffold has revealed many applications from plant based textiles and a solution for mopping up oil spills http://ecovativedesign.com/ and because fungi lack chlorophyll and exist on decaying material they can be grown on various substrates including some food wastes (Upcraft et al., 2020). The fermentation process also involves little energy consumption and can take place vertically with minimal and mainly compostable waste. In addition the production can take place near the end users, within urban areas and thereby reducing energy usage further.

Mycoprotien is a familiar and accepted food product in existence since the 1980s sold as Quorn. It is produced from Fusarium venenatum a filamentous mycelium and its development and subsequent release onto the market followed a 15 year research and development process and toxicity testing before approval (R, G and J, 1989). An additional body of scientific research has explored the broader health benefits of mycoprotein consumption (Coelho et al., 2020)(Derbyshire and Ayoob, 2019)(Finnigan et al., 2019). These Quorn products are currently in the form of analogue chicken burgers, nuggets and breaded cutlets and analogue ground beef (Finnigan, 2011) . Recent work undertaken by Ecovative Foods using Hericium erinaceus and Gandoerma applanatum claim to have developed upon the Quorn model by producing a whole muscle cut of meat. As whole cuts of meat account for 82% of the meat industry (FAO (Food and Agriculture Organization of the United Nations), 2020) analogue meats must compete with this end of the market to have a real impact and mycelium is capable of mimicking the texture of meat and contains similar amino acids and minerals.

Mycelium is high in protein with 20% of energy value from protein; low in fat, with 3% fat per 100g of product; low in saturated fat, with 1.5g saturated fatty acid per 100g and high in fiber with 6g of fiber per 100g. (Derbyshire, 2020). In addition it contains riboflavin, vitamin B12, phosphorus, zinc, and manganese (Derbyshire, 2020). Mycelium, as a percentage of its total protein, contains 41% essential amino acids, higher than most other plant based proteins (Finnigan et al., 2019). In a blind test conducted it has been shown that mycoprotein ingestion led to a slower and more consistent essential amino acid uptake compared with milk and has been shown to simulate greater muscle protein development than milk (Monteyne et al., 2020)

The results of life cycle analysis of mycoprotein show it has a similar environmental impact as chicken or pork. If agricultural or industrial residues or waste are deemed suitable for use as a growing substrate for mycelium it is agreed that costs in cultivation and environmental costs could be reduced considerably. Fermentation accounts for 50% of capitol costs while feed and cellulase account for most of operating costs. The price of mycoprotein per Kg of protein adjusted through Net Protein Utilization currently is comparable with beef or chicken (Upcraft et al., 2020). With further development of mycelium to mimic muscle tissue and the use of mycelium as a scaffolding to build both plant based and cell based analogue meats as well as fungi based products the future applications of mycelium seem promising.

Coelho, M. O. C. et al. (2020) ‘Mycoprotein as a possible alternative source of dietary protein to support muscle and metabolic health’, Nutrition Reviews. doi: 10.1093/nutrit/nuz077.

Derbyshire, E. and Ayoob, K. T. (2019) ‘Mycoprotein: Nutritional and Health Properties’, Nutrition Today. doi: 10.1097/NT.0000000000000316.

Derbyshire, E. J. (2020) ‘Is there scope for a novel mycelium category of proteins alongside animals and plants?’, Foods, 9(9). doi: 10.3390/foods9091151.

FAO (Food and Agriculture Organization of the United Nations) (2020) Meat market review, Food and Agriculture Organization of the United Nations.

Finnigan, T. J. A. (2011) ‘Mycoprotein: origins, production and properties’, in Handbook of Food Proteins. doi: 10.1533/9780857093639.335.

Finnigan, T. J. A. et al. (2019) ‘Mycoprotein: The Future of Nutritious Nonmeat Protein, a Symposium Review’, in Current Developments in Nutrition. doi: 10.1093/cdn/nzz021.

Monteyne, A. J. et al. (2020) ‘Mycoprotein ingestion stimulates protein synthesis rates to a greater extent than milk protein in rested and exercised skeletal muscle of healthy young men: A randomized controlled trial’, American Journal of Clinical Nutrition. doi: 10.1093/ajcn/nqaa092.

Poore, J. and Nemecek, T. (2018) ‘Reducing food’s environmental impacts through producers and consumers’, Science. doi: 10.1126/science.aaq0216.

R, A., G, B. and J, T. (1989) ‘CAMBRIDGE STUDIES IN BIOTECHNOLOGY 7. FOOD BIOTECHNOLOGY’, in Angold, R., G. Beech and J. Taggart. Cambridge Studies in Biotechnology, 7. Food Biotechnology. Ix+171p. Cambridge University Press: New York, New York, Usa; Cambridge, England, Uk. Illus.

Upcraft, T. et al. (2020) ‘Protein from Renewable Resources: Mycoprotein Production from Agricultural Residues’, in Computer Aided Chemical Engineering. doi: 10.1016/B978-0-12-823377-1.50165-8.

Willett, W. et al. (2019) ‘Food in the Anthropocene: the EAT–Lancet Commission on healthy diets from sustainable food systems’, The Lancet. doi: 10.1016/S0140-6736(18)31788-4.