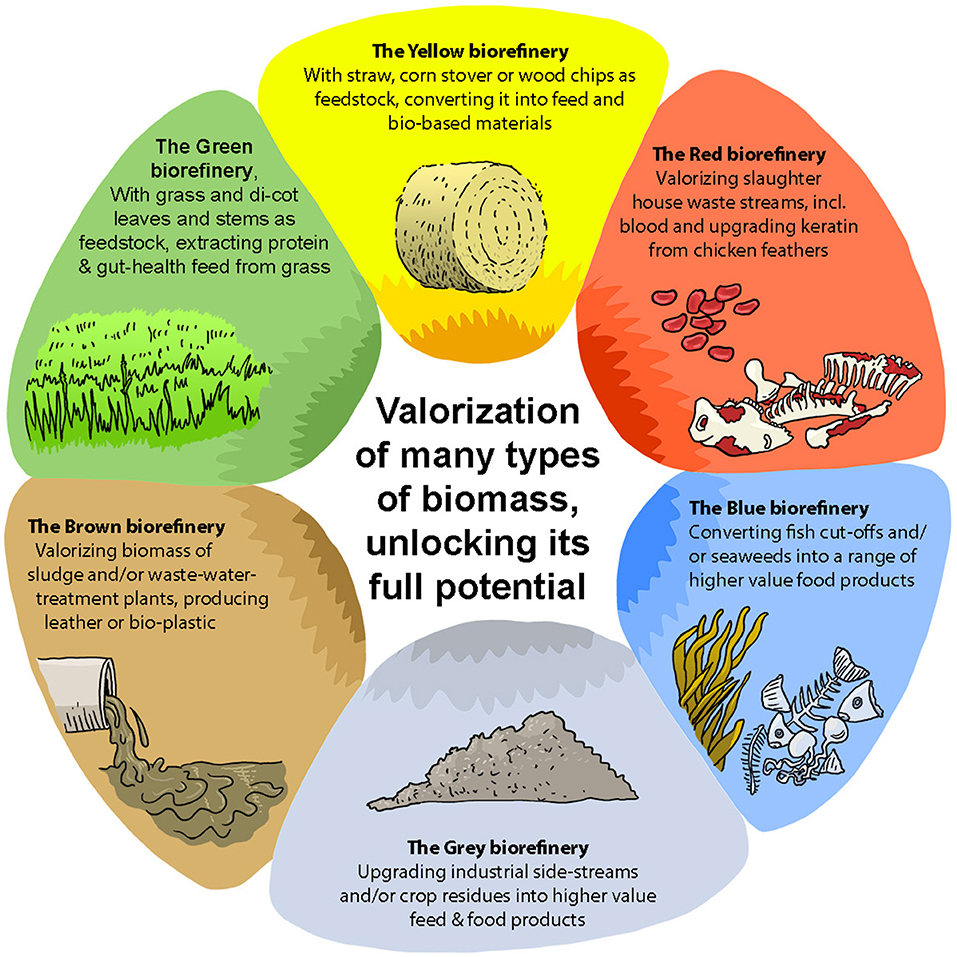

Lange (2022) categorises a series of various biorefineries through colour code to reflect the type of biomass and type of biomass processing. Below, Figure 1 depicts a colour code of the six basic types of biomass conversion. The colour coded system combines different types of biorefinery processing to reflect the recalcitrance of the biomass. Yellow biorefineries include the conversion and valorisation of cereal straw or wood chips after pre-treatment to make biobased products and feed from the cellulose or hemicellulose and lignin to a range of higher-value products. Red biorefineries involve the conversion of microbes or enzymes into protein-rich animal feed. Green biorefineries consist of extracting protein from the green parts of the plant, e.g., grass or leaves and stems of sugar beet, and the residual pulp after protein recovery can be sold as bulk cattle field. The main goal of green biorefineries is to develop animal feed from local protein sources, to substitute for soybean imports from main producer countries such as Brazil and China. Brown biorefineries is the suggested term for the valorisation of organic materials in sludge and wastewater treatment plants to produce new types of materials to substitute animal-based products. Blue biorefineries involve the upgrading of fish offcuts and seaweeds to a range of higher value products. Last, the grey biorefinery categorization includes the residue from food processing that can be converted into higher value feed and food products.

Green biorefinery is of emerging interest since the demand for feed proteins for livestock is increasing from the rise in global demands for meat and plant protein products due to the growing global population (Njakou Djomo et al., 2020). Green biorefineries are often described as multiple-product systems, with the potential range of products depending on the composition of the feedstock presented to the biorefinery. This multiple-product approach was born out of economic necessity, with single-product approaches often struggling to create sufficient revenue to cover the feedstock and subsequent processing costs (McEniy and O’ Kiely, 2014).

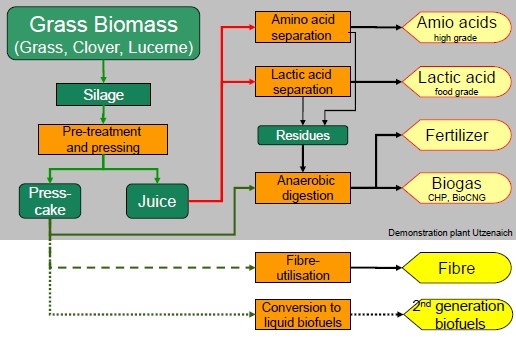

Green biomass includes grass from cultivation of permanent grass land, closure fields, nature preserves or green crops, such as lucerne, clover and immature cereals from extensive land cultivation. As shown in Figure 2, wet fractionation technology is used as first step to isolate the content-substances in their natural form. Thus, the green crop goods (or humid organic waste goods) are separated into a fibre-rich press cake and a nutrient-rich green juice. The press cake contains valuable dyes and pigments, crude drugs and other organics. The green juice contains proteins, free amino acids, organic acids, dyes, enzymes, and other organic substances. Green juice is used to generate products such as lactic acid and corresponding derivatives, amino acids, ethanol, and proteins. The press cake can be used for production of green feed pellets, as raw material for production of chemicals, such as levulinic acid, as well as for conversion to syngas and hydrocarbons (synthetic biofuels). The residues of substantial conversion are suitable to produce biogas combined with generation of heat and electricity. In Europe Green Biorefinery activities are concentrated in Germany, Denmark, Austria, Ireland and Switzerland (Kamm and Kamm, 2004).

The major advantage associated with the green biorefinery is the multi-product system, low-price feedstock that is available in large quantities, they may also resolve the problems of waste management and greenhouse gas emissions. The overall economic efficiency of the biorefinery is mainly determined by the economic return of the fibres. The grassy green feedstock is more easily pre-treated and fractionated into its basic constituent for biorefinery processing that ultimately reduces costing of the end-product formulation. A large variety of the secondary products can be extracted, isolated, and synthesized. Also, organic waste such as agricultural/forestry waste can be considered and utilized as a green feedstock (Badgujar and Bhanage, 2018). Dutch researchers developed a biorefinery for grass and other leaf material (alfalfa, beet, etc.). The economic efficiency was assessed by considering costs for grass (€70–80/tonne) more than those of leaves (€50–70/tonne). Fibres (representing 30% of the products by weight) were valued at approximately €100/tonne, other components at an average of €800/tonne of dry grass, making the use of grass in potential very cost-effective. However, fractionation of grass appeared to be burdensome and therefore costly. So major improvements should be completed in this area (de Jong and Jungmeier, 2015).

Bibliography

BADGUJAR, K. C. & BHANAGE, B. M. 2018. Chapter 1 – Dedicated and Waste Feedstocks for Biorefinery: An Approach to Develop a Sustainable Society. In: BHASKAR, T., PANDEY, A., MOHAN, S. V., LEE, D.-J. & KHANAL, S. K. (eds.) Waste Biorefinery. Elsevier.

DE JONG, E. & JUNGMEIER, G. 2015. Chapter 1 – Biorefinery Concepts in Comparison to Petrochemical Refineries. In: PANDEY, A., HÖFER, R., TAHERZADEH, M., NAMPOOTHIRI, K. M. & LARROCHE, C. (eds.) Industrial Biorefineries & White Biotechnology. Amsterdam: Elsevier.

KAMM, B. & KAMM, M. 2004. Biorefinery-systems. Chemical and biochemical engineering quarterly, 18, 1-7.

LANGE, L. 2022. Business Models, Including Higher Value Products for the New Circular, Resource-Efficient Biobased Industry. Frontiers in Sustainability, 3.

MCENIY, J. & O’ KIELY, P. 2014. 11 – Developments in grass-/forage-based biorefineries. In: WALDRON, K. (ed.) Advances in Biorefineries. Woodhead Publishing.

NJAKOU DJOMO, S., KNUDSEN, M. T., MARTINSEN, L., ANDERSEN, M. S., AMBYE‐JENSEN, M., MØLLER, H. B. & HERMANSEN, J. E. 2020. Green proteins: An energy‐efficient solution for increased self‐sufficiency in protein in Europe. Biofuels, Bioproducts and Biorefining, 14, 605-619.