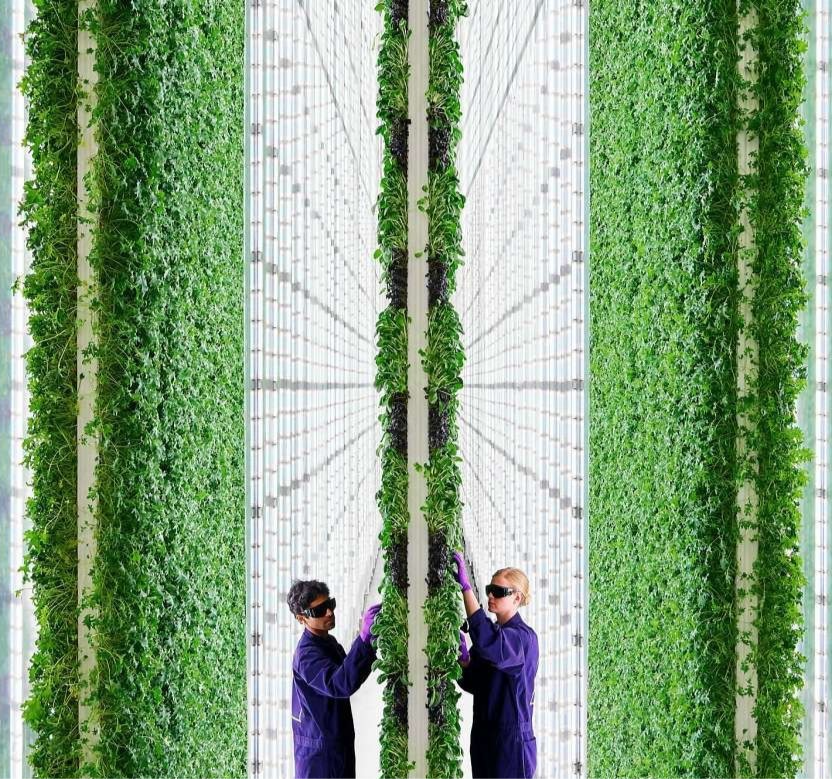

It’s a familiar line in the context of city planning and development. ‘Build up, not out’ – transitioning the development of our cities toward a high-rise model will cut commuters’ journey times, reduce emissions, and protect the biodiversity that would otherwise be paved over through the building of sprawling suburban estates. The concept of ‘Vertical Farming’ (VF) may not, however, be quite so well-known. Also termed Vertical Agriculture, the process involves growing crops indoors, in vertically stacked layers, like shelving in a store. The plants are grown in facilities where temperature, light, water, and other elements are controlled, allowing for optimum growth conditions all year round. Generally, produce grown in these indoor farms can be produced at a point in the supply chain, physically much closer to the end destination (supermarkets etc.). This, in turn, can lead to big reductions in the miles travelled, potentially reducing food waste.

The stacked nature of the facilities also means that the sprawl of traditional agricultural lands is avoided, and landscapes are therefore preserved. The lack of pesticides, and protection from the unpredictable nature of the elements has seen it become increasingly popular. Vertical farms have been installed in abandoned mine shafts, shipping containers, and derelict buildings. Farmers Weekly1 noted its global value to be £1.72 billion in 2018, with experts predicting this could rise to £9.84 billion by 2026. The US, and Japan are world leaders, but other countries uptake is seeing a steady increase too. VF, like most things, is no silver bullet. Where VF facilities are tied to the grid, the carbon footprint can be greater than traditional methods of production. Djavid Amidi-Abraham, of Agritecture2 calculated that a container farm connected to the New York grid produced roughly 8.19 lbs of CO2 for every lb of lettuce grown. This compared poorly with lettuce grown in California and transported traditionally. The produce grown in this case produced roughly 0.31 lbs of CO2 per lb of lettuce and considered waste due to transport. This is not to say VF is without hope as a sustainable alternative to traditional growth methods. OneFarm3, a Dutch VF company carried out a study that indicated VF can be far more efficient when connected to a renewable energy source, like wind power.

We do of course need to view these studies through a critical lens due to their potentially bias nature, but there is certainly some evidence to indicate VF will have a strong role to play in securing climate resilient crop production, certainly in major cities, going forward. The lack of soil in these aeroponic or hydroponic systems of growth means no pesticides, and issues such as salinity and waterlogging don’t threaten the crops. With electronic sensors guaranteeing the correct amount of heat, nutrients, and LED light, improved crop predictability is ensured. With up to 40% of the world’s food crops lost4 during the ‘farm to fork’ phase, this is invaluable. Additionally, the lower water consumption, and year-round growing capacities make VF worth persevering with. It’s going to be interesting watching its development as we move towards 2030, and the hopeful realisation of the UN’s Sustainable Development Goals.

Bibliography