Potential yield losses associated with machinery downtime

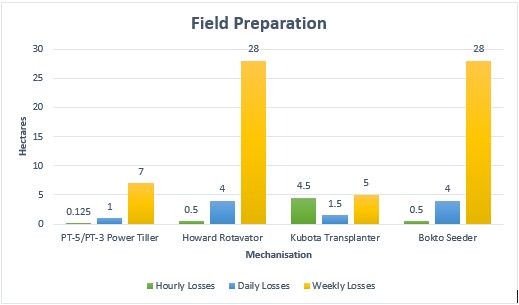

Now is a good time to assess results from the recent IRRI/NUI Galway project that also formed part of my thesis. After a few days off, some fresh thoughts on the project and subsequent results could be broken down and assessed. Firstly, a list of machinery involved in two stages of rice production were accumulated and potential yield losses resulting from machinery downtime were calculated. The first stage was field preparation. Figure 1 shows potential production losses associated with four machines in the field preparation phase.

Figure 1. Field Preparation losses.

Potential yield losses related to field preparation downtime. Four machines were assessed for potential yield losses associated with failure of rice mechanisation. High production units like the Howard Rotavator and the Bokto seeder resulted in identical production losses with 28 hectares arrears after one week of downtime. Hand operated machinery like the Power Tillers and the Kubota Transplanter resulted in less than 10 hectares of losses per week.

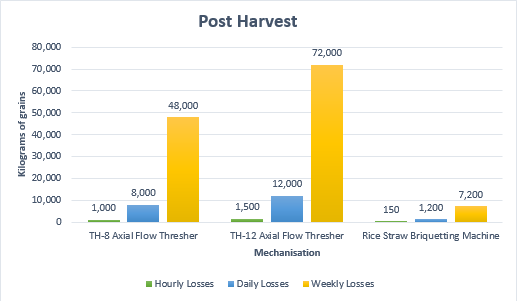

Figure 2 shows potential losses associated with post harvest. Three machines were assessed.

Figure 2. Post harvest losses.

Potential production losses related to post harvest downtime. The Axial Threshers resulted in the largest production losses. 72,000 kilograms of grain production could be lost with one week’s downtime. Daily losses for the threshers could be substantial with 8 to 12,000 kilograms of grain production lost. The briquetting machine could lose 7,200 kilograms per week.

Potential losses for machinery downtime is extensive. 3D printing of spare parts could help reduce these losses. However, the issue of spare parts here is debatable at best. Spare parts may not be the issue. Complete machine failure or poor operator use may be factors. 3D printing of spare parts to reduce downtime will likely need further research.