Visit to Isabela region

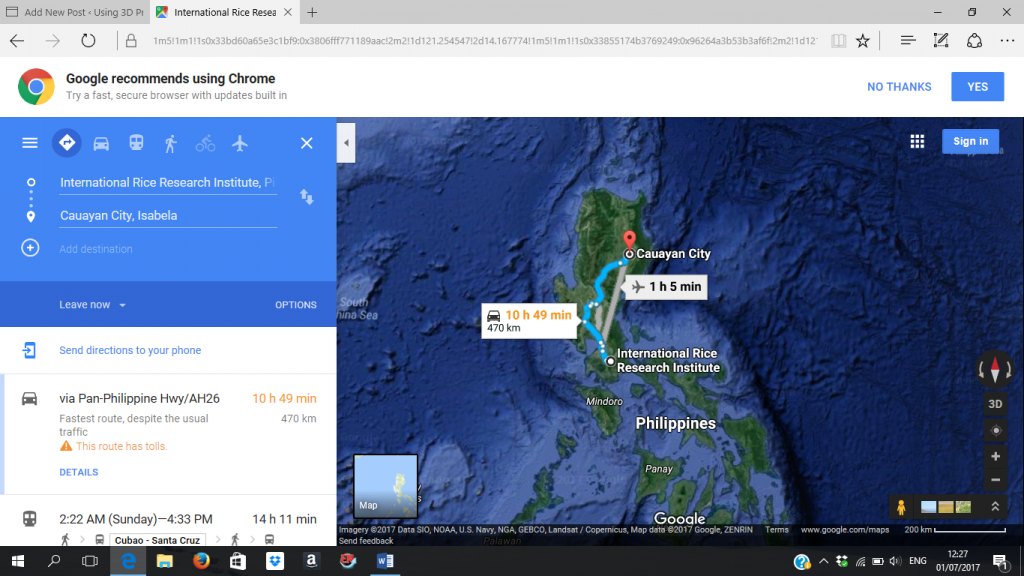

Tuesday morning at 4:30 am was the start of a long journey. We had organised meetings with Agricomponent, Phil Rice, Phil Mech, and some agricultural manufacturers affiliated with IRRI. The evening before I prepared the bag and had a quick glimpse on google maps to see how far we actually had to go. 470km’s of a spin doesn’t sound too bad if I’m honest but were in the Philippines where traffic can come to a standstill for hours and the speed limits don’t generally apply. The volume of vehicles on the road is just immense. Whatever google maps says you can add hours onto that. I was collected at the IRRI dorm by Anthony the driver. I asked how long it would take to reach our destination. He said, “it could be 14 hours sir”. My jaw dropped. Imagine how far one could go on a 14 hour flight! So it turns out we got there 12 hours and 10 minutes later having

only stopped twice. Not bad but the 6am traffic in Manila was just woeful. The landscape changes as you move up north. It doesn’t seem as squashed and busy as it is in the Luzon or Laguna regions. It’s also the heart of rice production in the Philippines. We seen some “mini” rice terraces and everywhere you looked there were rice paddies. You can see why the country depends on rice so much and why its such an important cash and subsistence crop. I noted that a lot of is done manually. It got me thinking in relation to my project.

only stopped twice. Not bad but the 6am traffic in Manila was just woeful. The landscape changes as you move up north. It doesn’t seem as squashed and busy as it is in the Luzon or Laguna regions. It’s also the heart of rice production in the Philippines. We seen some “mini” rice terraces and everywhere you looked there were rice paddies. You can see why the country depends on rice so much and why its such an important cash and subsistence crop. I noted that a lot of is done manually. It got me thinking in relation to my project.

A lot of the land preparation, planting, seeding, and harvesting done up north is done manually. Imagine the time saved and yield improvements if there was access to proper farm mechanisation? At this point I was guessing that the research I’m conducting with IRRI is genuinely important.

On Wednesday morning we met Agricomponent Cor. and had a chat with them about 3D printing of spare parts.

They believe it’s prototyping where the real time and costs are saved. The trend was similar with Phil Rice and Phil Mech, both subsidiary’s of the department of agriculture. Agricomponents workshop is monumental. I was surprised at how big it was and the work they do. Harrows, dryers milling machines which are all custom designed and built there and distributed all over the Philippines. Phil Mech are more into research and development.

Overall the visits were fruitful and the use of 3D printing something that excites Filipino manufacturers, workshops and farmers.