3D printing business model to support smallholder farmers in the Philippines

A survey was done to assess the possibility of a 3D printing business model to support smallholder farmers in the Philippines. Methodologies included garnishing structured feedback from workshops, repair specialists, spare part distributors and research bodies. 3D printing services could reduce the waiting time for spare parts, easing pressure on workshops, engineers, and contractors. In turn, it could maintain production for farmers using agricultural machinery repaired by 3D printed spare parts.

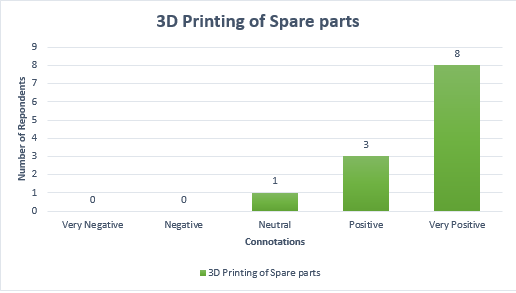

Figure 1. . Reactions after first hearing of 3D printing.

Reactions were mostly positive after hearing about 3D printing techniques. One respondent was neutral on the use of 3D printing. Lack of information on 3D printing technologies is likely a contributing factor.

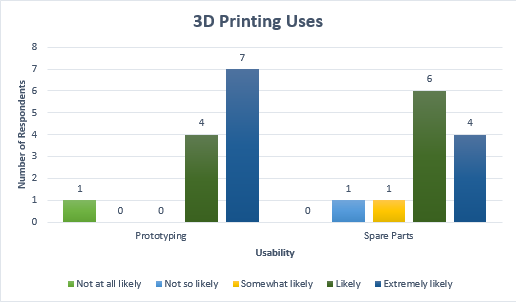

Figure 2 shows how likely or unlikely the respondents would use 3D printing for spare part replacement or prototyping. Overall, respondents were likely to use the technology for both spare part replacement and prototyping. Ten respondents were likely or very likely to use 3D printing for spare parts and eleven were likely or extremely likely to use it for prototyping.

Figure 2. 3D printing for prototyping and spare parts. Most respondents were likely to use 3D printing for prototyping and spare parts. One respondent was not at all likely to use 3D printing for prototyping.

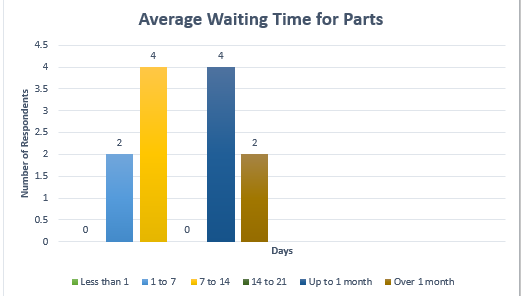

Figure 3 shows the waiting time for spare parts to be delivered to the respondent’s businesses. There was a mixture of short and long waiting periods. The businesses who wait longer for parts tend to use and import spare parts more often. The respondents who have shorter waiting periods would design and manufacture with repair in mind. They would use locally sourced materials and have an inventory of spare parts ready for use. Two respondents claimed it can take over one month to get spare parts for machinery.

Figure 3. Average waiting periods for spare parts. Spare part replacement was generally unavailable in less than one day. Depending on the part four respondents claim it takes 1 to 2 weeks to get replacements. Four claim it takes up to one month to get spare parts and two waits over one month for spare parts.

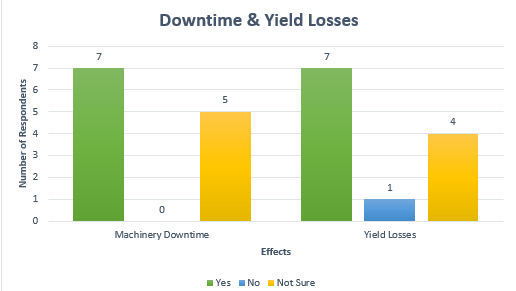

Figure 4 illustrates the respondent’s opinions on reduction in downtime and crop yield losses associated with 3D printing of spare parts. Seven respondents believe that 3D printing of spare parts can reduce machinery downtime and help crop yields. One respondent believed that 3D printing of parts had no influence on yield losses. Four respondents were unsure of both downtime and yield losses.

Figure 4. 3D printing of spare parts to reduce machinery downtime and potential yield losses. Most respondents believed 3D printing of spare parts could reduce machinery downtime and potentially help maintain production of crops. One respondent believed it wouldn’t help yield losses. Five were unsure if it could help downtime and four were unsure if 3D printing of spare parts could help yield losses.

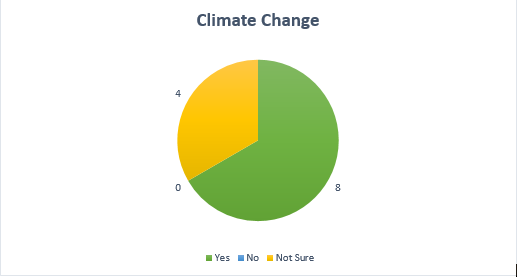

3D printing has potential to reduce pressure on natural resources. Figure 5 shows the views of the respondents between 3D printing and climate change. Eight of the twelve respondents believe 3D printing will be useful in combating climate change with four not sure.

Figure 5. 3D printing’s ability to combat climate change. Two-thirds of the respondents believe 3D printing can help combat climate change. A third were unsure. Lack of information or knowledge on climate change and 3D printing may be a factor.

The respondents were informed during the briefing sessions that 3D printing could reduce pressure on natural resources through reductions in waste. Figure 6 shows the respondents concerns related to 3d printing and waste reduction.

Figure 6. 3D printing and waste reductions. Two-thirds of respondents believe 3D printing can reduce waste associated with manufacturing of parts. Three were unsure and one claimed it wouldn’t reduce waste.

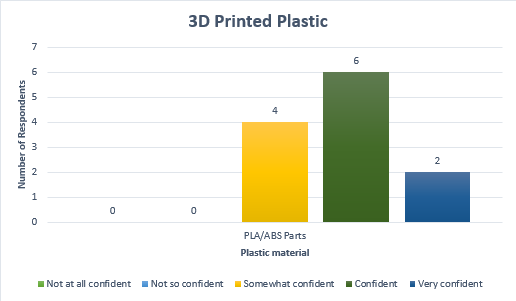

Respondents were showed an ABS printed nozzle for a Honda power washer as an example of plastic printed parts. Figure 7 shows how confident respondents would be using PLA/ABS printed parts as replacements to original equipment.

Figure 7. Using 3D printed plastic parts. Most respondents would be confident using 3D printed plastic parts. Four were unsure of using plastic as a replacement. Lack of testing plastic parts may be a factor in their uncertainty.